Shaping the Future: How Industrial 3D Printing is Revolutionizing Manufacturing

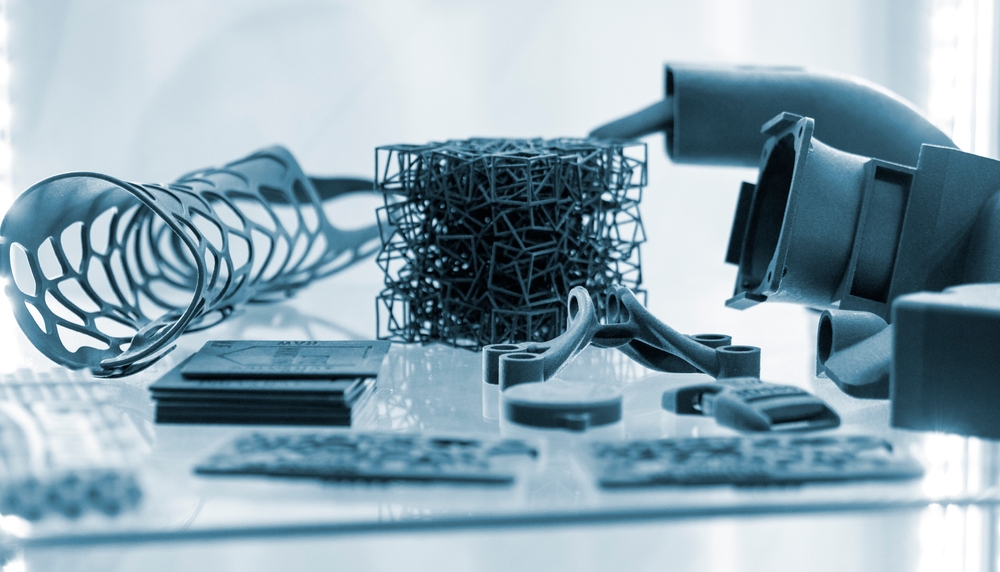

In the ever-evolving world of manufacturing, a new star is on the rise. 3D printing, or additive manufacturing, is no longer a novelty used for creating trinkets and prototypes. It is becoming a pillar of industrial operations, changing the way manufacturers design, produce, and distribute products.

A New Dimension in Manufacturing

Historically, manufacturing was a subtractive process. A block of material would be reduced, bit by bit, until the desired product emerged. This method, while effective, is time-consuming and resource-intensive. In contrast, 3D printing builds products layer by layer, using only the necessary material. This process was first developed in the 1980s but only recently has it become advanced and affordable enough for widespread industrial use.

Industrial 3D Printing: A Rising Trend

As technology improves, more and more businesses are recognizing the potential of 3D printing. According to a report by SmarTech Analysis, the market for 3D printing in manufacturing is projected to reach $5.01 billion by 2027. This growth is driven by a range of factors, including decreased production costs, increased operational efficiency, and the ability to create complex geometries that would be impossible with traditional manufacturing methods.

Impact, Benefits, and Challenges

The implications of industrial 3D printing are far-reaching. For one, it allows for more customization. Each print can be different without requiring additional time or resources. This enables manufacturers to cater to individual customer needs and create unique, tailored products. Additionally, 3D printing can significantly reduce waste, leading to more sustainable manufacturing practices.

However, this technology is not without its challenges. The initial investment in 3D printing equipment can be high, and there is a steep learning curve to master the technology. Moreover, 3D printed products can sometimes lack the strength and durability of traditionally manufactured goods.

Turning Insights into Actions

While the adoption of 3D printing in manufacturing is still in its early stages, the trend is clear. Manufacturers who embrace this technology stand to gain a competitive advantage in the evolving industrial landscape.

Quick Tips for Adopting 3D Printing in Your Business

- Start small: Incorporate 3D printing gradually into your operations to minimize risk and maximize learning.

- Collaborate with experts: Partner with 3D printing experts to overcome initial learning hurdles and leverage their experience.

- Embrace customization: Utilize the customization potential of 3D printing to differentiate your products and cater to individual customer needs.

- Consider sustainability: Use 3D printing to reduce waste and promote more sustainable manufacturing practices.

In conclusion, industrial 3D printing is more than a passing fad—it’s a game-changer. By reshaping the way we design, produce, and distribute products, it is setting the stage for a new era in manufacturing. While the adoption of this technology comes with its challenges, the benefits—customization, efficiency, sustainability—make it a compelling choice for forward-thinking manufacturers. As we move into the future, those who embrace this trend will lead the way in the world of manufacturing.